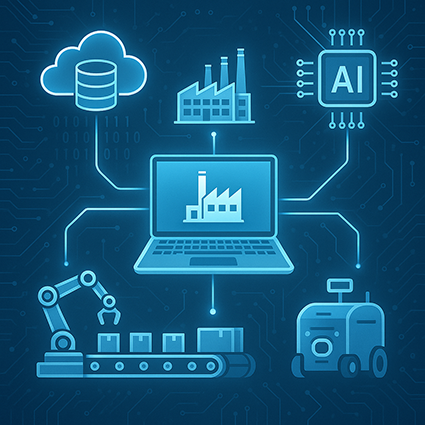

By integrating ERP, DRP, automation control systems, robotic arms, and belt conveyors, a highly efficient and intelligent value chain is created to enhance management efficiency.

Promoting digital and intelligent transformation in businesses through OA, CRM, BI, computer vision, and other systems, improving operational efficiency capabilities.

The client submits their business needs, goals, and challenges.

This step involves gathering client needs, defining scope, setting objectives, and creating an initial technical solution proposal.

Focuses on creating detailed designs for both software architecture and hardware integration, considering scalability, performance, and future growth.

Involves coding, debugging, and programming software systems, as well as developing control logic for automation hardware like robotic arms and conveyors.

Systems are integrated, ensuring smooth communication between software, hardware, and other external systems, followed by extensive debugging and adjustments.

The system undergoes rigorous testing, including functional and performance checks, and the client verifies that the system meets their expectations and requirements.

After final testing, the system is deployed on-site or to cloud platforms, with all hardware installed and configured for live use.

Ongoing support, monitoring, and troubleshooting are provided to ensure the system operates efficiently; Performance improvements are made as needed.